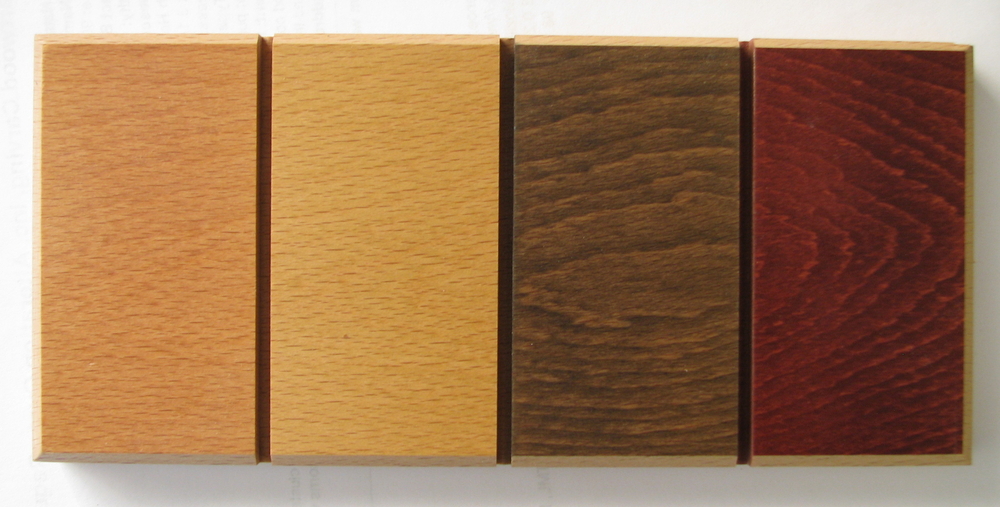

What is the best way to Stain your Stain Grade (Beech)

Tips on Staining

European Beech

Introduction:

There are too many stains, processes, types of finishing equipment, finishing techniques, and products and processes to write about them all. Our attempt here is to discuss some basic ideas that will assist the finisher in achieving the desired look of finish on European Beech.

First:

All wood is (hygroscopic) and will absorb stains and finishes differently depending on the porosity and cell structure of the wood species. Some hardwoods like Hard Maple resist the absorption of stains as the grain structure is tight and interlocking and cells are small. Some hardwood like European Beech, although it is as hard as Hard Maple, has larger pores and does not have tight interlocking grain. Both species are contemporary, closed grain woods that sand smooth, finish to a high polish and do not look “heavy grained” when stained or finished like open grain hardwoods such as Oak. Since Hard Maple doesn’t take stains deeply and requires multiple coats, it will lose almost all signs that it is wood. The stain will hide the grain, especially on darker finishes. European Beech on the other hand, even though it sands to a high polish, will absorb more stain and will show the grain of the wood, even on darker finishes. If the desired look is to mute the grain, using a sanding sealer to fill the pores of the wood would allow European Beech to achieve that look as well.

Why finish and stain wood:

1) To protect the wood from dirt

2) Protect it from gaining moisture.

3) To enhance the color and grain of the wood and to bring out the natural beauty and enhance it with color.

Quote from a famous wood finishing guru,

“100% of finishing problems are preparation or application.”

Preparation:

Books have been written on this topic. Many problems can be traced back to poor

preparation. Following are some basic steps to remember.

1) Make sure to use good quality sandpaper.Carbide is the best.

2) 180 is normally high enough grit. (Over sanding will waste time, $ , and can cause the finish to not bind as well.)

3) Make sure to round all edges, stains and finishes do not bind well to a square edge.“ It is like trying to get finish to stay on the edge of a razor blade.”

4) Make sure sanding is uniform, no over or under sanding. (Watch for glue spot as well.)

Finish:

For European Beech, we have been told that water-based dye stains work the best as the look is more uniform and it will not look blotchy or gritty like oil-based wipe-on/wipe-off stains. The most common problem is the blotchy or gritty look oil stains leave when the stain is wiped off leaving the asphaltom or gilsonite (dark tar based

colorants) lodged into the pores of the wood. This also causes the grain to “POP”. Spray, no-wipe will minimize or reduce the grain pop or gritty, blotchy look.

Colorants that readily flow into the grain and wipe off cleaner will have more grain definition such as asphaltom, gilsonite and transparent oxide colorants. Other

colorants may penetrate the hardwood better and do not wipe off as clean, which

produces less grain definition. Also, lower viscosity stains tend to have more grain definition and higher viscosity stains tend to have less grain definition.

European Water Base Stain Technology or Hydro Stains

Advantages:

- Factoring in a spray application, and in-house color matching, staining cost in labor and material may be lowered by 30% or more.

- Make only the amount of stain you need, further cutting costs by minimizing waste.

- Making the stain where you need it, “on time”, no longer relying and waiting on an outside supplier.

- Many existing colors can be matched with the Hydro stains.

- For Beech and Maples, European Hydro stain technology is considerably more uniform than any wiping stain.

- In many cases, deep colors are achieved in one step rather than two.

- Dry times of Hydro Stains are twice as fast as the fastest wiping stain.

- Hydro stains are “green”; V.O.C.’s from staining would be virtually eliminated.

- Hydro stains achieve maximum uniformity on difficult to stain woods such as Beech and Maple. Pre-treatment of these woods would be eliminated.

- Because wood is made with water, Hydro stains have a natural relationship

with wood, and therefore are the most user friendly of spray stain applications. - Hydro stains are compatible with most finishes.

Disadvantages:

- Not all stain effects can be replaced with the Hydro stains.

- Open pore woods such as oak and hickory achieve maximum grain strike with wiping stains.

NOTE: Optional specialty colors may be offered with the use of Hydro stains as a Pre-stain under solvent wiping stain. This achieves the deepest of colors with clarity, uniformity and definition.

Conventional Staining Process

Conventional application of stain is generally applied by a “spray and wipe” process using solvent base stains. The stain is sprayed on, wiped off, and then must dry. As a wiping stain, it must be formulated to dry slowly, or what is known as an open time, to enable time to wipe the stain evenly.

Advantages:

- Wiping stains require relatively little training.

- Heavier pigments in these stains enhance the grain in open pore woods such as oak and hickory, producing a strong grain strike.

Disadvantages:

- Wiping stains on woods such as beech, maple and birch usually require a pre-treatment to reduce blotchy results; this step adds additional labor and material V.O.C.’s.

- From solid woods to veneers, uniformity of color is not always even.

- Application of a wiping stain takes 3-4 times longer than spray only stains.

- Dry times may vary from 45 minutes to several hours.

- Deep colors usually require an additional color step such as a spray only pre-stain.

- Solvent base wiping stains are the single highest exposure of bodily contact to toxic fumes. Fumes are absorbed not only through the lungs, but also through eye membrane and the skin.

- Bleed back of stain from pores and crevices between frames and panels is a common occurrence requiring the additional labor for re-wetting and removal.

- Solvent base stains are toxic. They are some of the highest in V.O.C.’s of

all finishing products. Wiping stains must be removed by hand; rag

marks and hand prints are inevitable, costing time and money to repair. - Solvent base stains are not considered ‘green’.

- Solvent base wiping stain rags produce waste.

- Used rags are flammable and a common reason for shop fires.

- Rags leave behind cotton fibers in the wood, which must be sanded out

of the finish. Used rags must be dried and disposed of carefully. - Much of the wiping stain is wasted. As much stain is left in the rags as in on the wood.